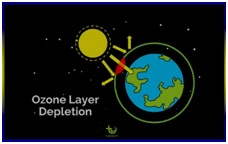

We all have definitely heard about the ozone layer at the school level, college level, or maybe at a higher education level. This is the layer of atmosphere that is present 35 miles above the ground. This layer of Earth protects the earth from harmful radiation and ultra-violet radiation from the sun. it usually reflects these ultraviolet rays back into space. This process is also necessary because these rays are harmful to plants and animals and all the living organisms on the earth.

In the middle of the 1980s, it was revealed that the refrigerants being used in many air conditioning systems are harmful and cause environmental issues as well as cause damage to the ozone. It is a plaque for the world as it is the cause of ozone depletion, which is the protective layer of the earth.

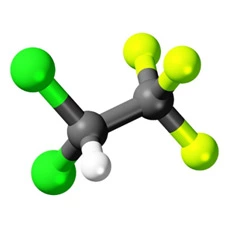

In the early days, the most commonly used refrigerants were chlorofluorocarbons ( CFC ) and hydrochlorofluorocarbons( HCFC ). They contain chlorine, fluorine, and carbon. And chlorine is the main cause of ozone depletion.

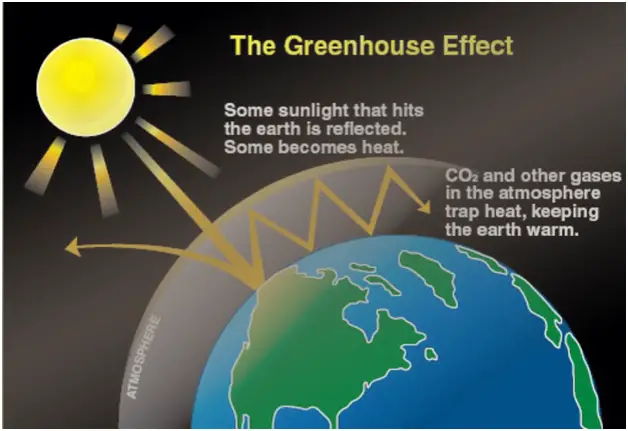

To reduce the effect of these harmful refrigerants and to protect the ozone from depletion many countries are signing protocols like the Montreal Protocol in 1987 and the Kyoto Protocol of 1997. They aim to reduce the Greenhouse effect caused sue to the emission of these harmful gases by man.

Do you contribute your part to save the mother nature ?

Greenhouse gases :

Greenhouse gases are as follows :

- Carbon dioxide

- Watervapor

- Methane

- Ozone

- Carbon monoxide

- Nitrogen dioxide CFCs, HCFCs, HFCs

What is a refrigerant

Refrigerant is actually a chemical used in air conditioning systems, its main function is to absorb the heat from the environment and cools the environment, the process is known as refrigeration.

Various refrigerants are available in the market and some of them are discussed in this article.

Types of refrigerant

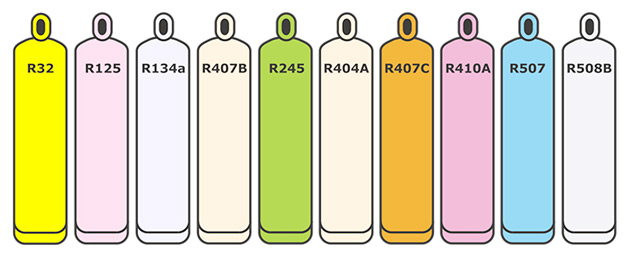

Commonly used refrigerants are :

Most commonly used will be the last ones R-134A and R-407C and R-410A

Cfc refrigerants

About 70 years ago their discovery take place. They are usually harmful to the respiratory system of humans and contribute to the depletion of ozone. Although their production was banned in 1995 still it is in use. The most common that are still being used are

- R-11 CCl3F

- R-12 CCl2F2

- R-114 CClF2CClF2

- R-113 CCl2FCClF2

- R-115 CCl2CF3

Hcfc refrigerants

They are considered haloalkane due to the presence of methane and ethane in combination with fluorine and chlorine. They exist for a shorter period of time hence they cause less damage to the ozone layer. EPA is aiming to phase it out completely by 2030. Commonly used ones are as follows :

- R-22 CHClF2

- R-123 CHCl2CF3

Hfc refrigerants

This is the one refrigerant that is free from chlorine and hence it is non-destructive with little effect on global warming. Commonly used refrigerants are :

- R-134A CH2FCF3

- R-125 CH2CF3

The Kyoto Protocol mentioned 6 greenhouse gases and this is not present in the marked list of the gases that will be phased out in 2030. For this reason, it is more desirable and is excessively used in the HVAC industry.

How does refrigeration work

Air conditioning technology or phenomena is based on refrigerant. Aiming to get air conditioning or cool air without refrigerant is impossible! it is usually present in the air conditioning coils of the air conditioning system. It will absorb heat from the environment as mentioned above and then move from low lower-pressure gas to high-pressure liquid. Hot air will blow it to the exterior of the air conditioning system where it cools and returns back. The fan located inside will blow it into the coils and the cycle goes on!

Refrigerant manufacturers

Top refrigerant manufacturers are given below

- 3F

- Meilan chemical

- Zhejiang Juhua

- Daikin

- Linde.com

- Maxichem

List of refrigerants

R 32

It is a type of refrigerant belonging to the HFC family. Chemically it is known as difluoromethane with the formula CH2F2. It is actually more preferred over other refrigerant gases as it causes a low Global warming effect.

R-410A and R-407A are used as a combined mixture in place of other ozone-depleting gases like R-22 because both R-410A and R-407A have zero ozone depletion potential ( ODP ). R32 is present in significant numbers in both these gases and it is easily available.

Global warming potential ( ODP ) and Ozone Depletion Potential :

As we all observe, the overall temperature of the world is increasing day by day and this is adversely affecting the lives of humans as well as animals. Global warming has become a plague for the world. The discovery of the greenhouse effect that is caused due to these refrigerants is now under great discussion to replace these ozone-depleting gases with some better option. This approach is being used by the HVAC industry to produce some better refrigerants with a minimum global warming effect and ozone-depleting potential.

Usually, manufacturers are trying to remove refrigerants like R-410A, R-134A, and R-407C with some refrigerants having little Global Warming Potential value for example R32. Its boiling point is -51˚C.

R-32 is another advantage in that it uses a very less amount of refrigerant, it only uses about 78% of the refrigerant for working. Japan is using this since 2013 for its latest products.

Flammability :

It comes under level A2 of flammability so it require high care.

Similarity with R-410A :

Operating condition of R-32 is similar to the one with R-410A. moreover they have the same performance.

We can study this by comparison shown below. You will understand how their operating capability and functionality is similar. Let’s compare the saturation steam comparison between R32 and R410A.

| Temperature | -20 | 0 | 20 | 40 | 60 | 65 |

| R32 | 0.30 MPa | 0.71 MPa | 1.37 MPa | 2.38 MPa | 3.84 MPa | 4.29 MPa |

| R410A | 0.30 MPa | 0.70 MPa | 1.35 MPa | 2.32 MPa | 3.73 MPa | 4.17 MPa |

Inferences :

They have same operating temperatures

Both have same piping used

Ether is used as oil in both of the refrigerants

Tools and instruments used are also the same for both refrigerants like charge hose, vacuum pump adapter, refrigerant recovery tool, etc.

Difference :

Only refrigerant recovery cylinder can not be shared.

Advantages and disadvantages :

| Advantages | Disadvantages |

| It has zero ozone-depleting potential ( ODP ) | Toxic |

| Global warming is about 3 times less than that of R-410A | Need more precaution |

| The charges required by R32 is less as compared to R410A due to its lower density | Discharge temperature is very high that will result in the degradation of oil, damaging components |

| It has a high volumetric capacity | Discharge temperature is needed to be maintained by a considerable and efficient design. |

| The critical temperature is high, hence have high COP | |

| Easy to be produced as it consists of a single component |

Results :

This refrigerant is obviously eco-friendly so it is a good replacement for some refrigerants like R22 and R410A.

It is a common belief of scientists that if they succeed in replacing the harmful refrigerants that cause global warming and have high ozone-depleting potential, they will be able to reverse the ozone in a condition in which it was in the 1980s. We all should contribute to phase out products that have non-zero ODP.

| Refrigerant | R134A | R32 | CO2 | R1234yf | R11 | R22 | R410A | R407C |

| Global warming | 1430 | 675 | 1 | 4 | 4750 | 1810 | 2088 | 1770 |

| Ozone depleting potential | 0 | 0 | 0 | 0 | 1 | 0.055 | 0 | 0 |

It has been observed and noticed that hydrochlorofluorocarbon refrigerants R-22 is not healthy for the environment and is not eco-friendly. EPA is being worked that how to phase out such harmful refrigerants and ban them altogether. This process of phasing out was starting in 2010 and then in 2015 and they aim to make it completely illegal to use them by 2030.

Most of the equipment and instruments that involve the use of refrigerants are being used in the residencies, industrial and business places where everybody aims to use the eco-friendly and efficient alternative of Freon that is very harmful.

Due to some reasons mentioned above, some of the eco-friendly and safe refrigerants have been introduced explained below. You will notice that each refrigerant has its own pros and cons in addition to the safety measures and precautions to be taken for its use.

R-134A

Chemically it is a haloalkane known as Norflurane commonly referred to as R-134A. In contrast to R32 it is not a blend or not a mixture of two refrigerants, it just simply consist of one single component. So it doesn’t require complex machinery for recovery. Because according to EPA regulations if we are dealing with the recycling of a chemical that blends two then you will surely need a separate machine for each of the components.

In most commonly used vehicles it is the only approved alternative of R-12 but retrofitting requires a proper procedure to avoid any problem and to ensure safety measures and hazards can be avoided in this manner.

Retrofitting :

- This is a simple and easy process that includes

- Change vehicles’ accumulator or dryer

- Removing an old compressor oil

- Removing vehicle’s a/c high-pressure switch

Precautions :

- It should be done with great care

- Make sure to remove all R-22, because if it remains in the system it will cause contamination and lead to many complex problems.

Effects of cross-contamination :

- It will make decrease the reliability of the cooling system of vehicles

- Raise the pressure of compressor head

- It can fail the system

- R-134A requires a special oil blend of either polyethylene or esters like pylon esters

Advantages :

R-134A refrigerant is considered eco-friendly and good for the environment because it has no effect on the ozone layer as it has an ozone depletion potential of zero value. In spite of all these advantages and positive aspects still, there are some countries that are looking for some much better alternative than that of R-134A. But still, it is being used in many countries and regions and is sold and purchased in larger amounts at the auto-shops.

R-407C

Because of the similarity in thermodynamic properties between R-407A and R-22, it is the best alternative to R-22 refrigerant. Actually a mixture or a blend of pentaflouroethane, difluoromethane, and 1,1,1,2-tetrachloroethane. Usually packaged air conditioner or split air conditions use this refrigerant that is considered the best alternative worldwide. It is mainly used in the following air conditions :

- Packaged air conditions

- Split air conditioner

- Water chillers

- Light air conditioner

- Direct expansion air conditioning system

- Medium temp air conditioning system

The equipment and appliances that mainly uses nitrogen as holding charge are considered to work best with refrigerants like R-407A as it uses pylol ester oil. Moreover, it can be retrofitted on the R-22 system but this procedure will surely include an oil change.

Advantages :

- It is safe and eco-friendly

- Best alternative and replacement to R-22

- It has zero Ozone Depletion Potential ( ODP )

- Available in drums and cylinders

- It can be purchased online from websites like Amazon.com or some supplier of refrigerant

R-404A

Is r410a toxic to humans? No. R410a is widely accepted safe refrigerant with an ozone depletion potential of zero similar to R-407A and R134A. it usually works between -49˚ F and 59˚ F. this wider temperature range make it more practical in industrial units.

Properties :

- The composition is simple and is similar to R-22 and gives maximum output performance.

- It does not react with air or water hence, it is safer

- Non-flammable

- Colorless

- Odorless

Precautions :

Since working and handling of each refrigerant require suitable safety measures and precautionary measures so to avoid any hazards. Some of the necessary precautions are as follows :

- Frostbite can be caused by direct contact

- Exposing to fire or elevated temperature will rupture the tank

R-404A can be purchased from a specialized person who knows about heating and cooling products, moreover, they can be purchased online from different websites like Amazon.com

R-410A

There was a protocol approved in 1987 known as the Montreal Protocol to remove gases that are the cause of ozone depletion. R-410A and R-407A are used as a combined mixture in place of other ozone-depleting gases like R-22 because both R-410A and R-407A have zero ozone depletion potential ( ODP ). R32 is present in significant numbers in both these gases and it is easily available.

Two refrigerants, difluoromethane, and pentaflouromethane blend and mix to form R-410A which have no effect on depletion of ozone mean a non-ozone depleting refrigerant that has enhanced efficiency than R-22 and R407C.

Advantages :

- It does not use chlorine

- It has a higher refrigeration capacity and pressure

- Enhanced performance

- More desirable

- Preferred by many manufacturers

Disadvantage :

It can’t be used as an alternative to Freon in the R-22 air conditioning system because its pressure is higher and it will require a pressure gauge.

How to recharge r410a refrigerant

It was in January 2006 when the EPA or Environmental Protection Agency banned the production of air conditioning units that fail to achieve a SEER or Seasonal Energy Efficiency Ratio of 13. Until that time, R22 was the refrigerant most commonly used. But, R22 didn’t meet the standard of 13 SEER. This is why most of AC units today use the refrigerant called R410A.

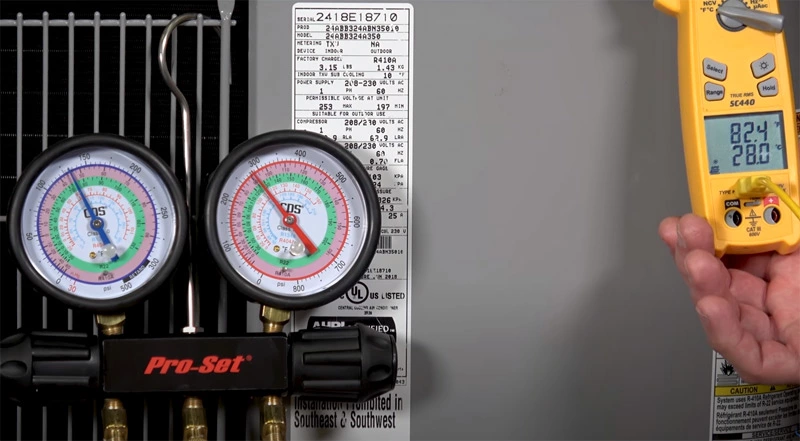

These refrigerants differ not just in composition but even in the specific processes used for charging the system. The required tools to charge a system with R410A different from the ones used to charge R22.

Before you recharge R410A refrigerant, make sure that the system doesn’t have any leaks. If there is a leak, a repair is necessary before you can recharge it.

Follow these steps to recharge R410A refrigerant:

- Inspect the blower wheels, blower motor speed, and coils to be sure that they all operate properly. Check the flow of air with the use of temperature rise method. Check the pressure drop across the coils with the use of coil specification sheets of the manufacturer. This airflow measurement can be used to locate the evaporator load so it needs to be accurate.

- Inspect the system operating pressures. You need to attach the manifold gauge’s hoses to the suction service valves and pressure taps on the liquid. The service valves are located anywhere in the outside cabinet although they are often found close to the coil.

- Read and take note of the information on pressure gauges for suction and liquid using paper and pencil.

- Measure and record outdoor temperature using an outdoor thermometer.

- To measure dry bulb temperature, put the thermometer in the area where air enters the indoor unit in return duct. Use wet cloth for wrapping the thermometer bulb and measure wet bulb temperature just how you measured the dry bulb temperature and record the results. The step is important as it locates the load with main effect on the system pressures.

- Identify sub-cooling by measuring the liquid line temperature. Use liquid line thermometer with probe that you can tightly attach to the line. Put the attachment about 6 inches from liquid service valve. Take note of the measurement results.

- Connect hoses from the manifold gauge to pressure taps on the suction and liquid service valves. Calculate and record the suction and liquid pressures. Measure high side pressure at service valve pressure tap for liquid line. A pressure conversion chart can be used for changing high side pressure into saturated temperature. Subtract liquid line temperature from saturation temperature of the R410A refrigerant in condenser to determine the sub-cooling value. Refer to the manufacturer’s data sheet to know the right operating pressured for situations found for measured air. Check the sheet for required sub-cooling levels.

- You can now charge the system with adequate R410A to adhere the specification of the manufacture if there is an extremely low sub-cooling issue according to the information on the data sheet. It is probably the result of lack of refrigerant if it is the case. Too high sub-cooling temperatures might be the result of excessive refrigerant in the condenser. It can also be because of failed Thermostatic Expansion Valve (TVX) or line restriction. You need to check the low and high side pressures to know if any of the problems exist.

- If the TVX works properly and no line restriction is present, siphon off sufficient R410A refrigerant until the pressure reading reaches the level recommended by the manufacturer. A refrigerant recovery machine should be used for safe transport of the coolant because releasing R410A to the air is considered illegal.